Toyota Yaris: Air Conditioning Unit / Installation

INSTALLATION

PROCEDURE

1. TEMPORARILY INSTALL AIR CONDITIONER UNIT ASSEMBLY

(a) Temporarily install the air conditioner unit assembly to the instrument panel reinforcement assembly with the 3 bolts.

2. INSTALL INSTRUMENT PANEL REINFORCEMENT ASSEMBLY WITH AIR CONDITIONER UNIT ASSEMBLY

(a) Engage the clamps.

| *a | Guide | *b | Clamp |

| Install in this Direction | - | - |

(b) Connect the connector.

(c) Engage the guides to install the instrument panel reinforcement assembly with air conditioner unit assembly as shown in the illustration.

(d) Install the 6 bolts.

Torque:

Bolt A :

31 N·m {316 kgf·cm, 23 ft·lbf}

Bolt B :

25 N·m {255 kgf·cm, 18 ft·lbf}

(e) Temporarily install the nut.

NOTICE:

Do not fully tighten the nut.

3. INSTALL NO. 1 INSTRUMENT PANEL BRACE SUB-ASSEMBLY

(a) Install the No. 1 instrument panel brace sub-assembly with the bolt and nut.

Torque:

Bolt :

20 N·m {204 kgf·cm, 15 ft·lbf}

Nut :

18 N·m {184 kgf·cm, 13 ft·lbf}

(b) Temporarily install the screw.

NOTICE:

Do not fully tighten the screw.

4. INSTALL AIR CONDITIONER UNIT ASSEMBLY

(a) Tighten the 3 bolts, screws and nut in the order shown in the illustration to install the air conditioner unit assembly.

Torque:

Bolt :

9.5 N·m {97 kgf·cm, 84 in·lbf}

Nut :

6.0 N·m {61 kgf·cm, 53 in·lbf}

5. INSTALL INSTRUMENT PANEL WIRE

(a) Engage the clamps to install the instrument panel wire.

| *a | Guide | *b | Clamp |

(b) Connect the each connector.

(c) Connect the instrument panel wire with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

(d) Engage the guides to connect the 4 ground wires.

(e) Install the 4 ground wires with the 4 bolts.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

| (f) Engage the clamp. |

|

(g) Connect the connector.

| (h) Install the ECU integration box RH with the 2 nuts and bolt. Torque: 8.0 N·m {82 kgf·cm, 71 in·lbf} |

|

| (i) Engage the clamps. |

|

6. INSTALL POWER DISTRIBUTION BOX ASSEMBLY WITH MULTIPLEX NETWORK BODY ECU

Click here

7. INSTALL NO. 3 INSTRUMENT PANEL TO COWL BRACE SUB-ASSEMBLY

Click here

8. INSTALL METER MIRROR SUB-ASSEMBLY (w/ Headup Display)

Click here

9. INSTALL COOLER UNIT DRAIN HOSE GROMMET

| (a) Install a new cooler unit drain hose grommet. NOTICE:

|

|

10. CONNECT DRAIN COOLER HOSE

| (a) Connect the drain cooler hose. |

|

11. INSTALL NO. 4 DASH PANEL INSULATOR PAD

(a) Engage the 2 clips to install the No. 4 dash panel insulator pad.

12. INSTALL FRONT FLOOR CARPET ASSEMBLY

(a) Install the front floor carpet assembly with the 2 clips as shown in the illustration.

13. INSTALL FRONT SEAT ASSEMBLY LH

Click here

14. INSTALL FRONT SEAT ASSEMBLY RH

HINT:

Use the same procedure as for the LH side.

15. INSTALL NO. 1 HEATER TO REGISTER DUCT SUB-ASSEMBLY

| (a) Engage the clamp to install the No. 1 heater to register duct sub-assembly. |

|

(b) Install the clip.

16. INSTALL NO. 2 HEATER TO REGISTER DUCT SUB-ASSEMBLY

| (a) Engage the clamps to install the No. 2 heater to register duct sub-assembly. |

|

(b) Install the clip.

17. INSTALL CENTER HEATER TO REGISTER DUCT SUB-ASSEMBLY

| (a) Engage the clamp to install the center heater to register duct sub-assembly. |

|

(b) Install the clip.

18. INSTALL STEERING COLUMN ASSEMBLY

Click here

19. INSTALL NO. 1 AIR DUCT

| (a) Engage the claws and clamps to install the No. 1 air duct. |

|

(b) Install the 2 bolts.

20. INSTALL INSTRUMENT PANEL ASSEMBLY

Click here

21. CONNECT INLET HEATER WATER HOSE

| (a) Connect the inlet heater water hose with the marking (white) facing up and engage the clip within the area shown in the illustration. NOTICE: Do not apply excessive force to the inlet heater water hose. |

|

22. CONNECT OUTLET HEATER WATER HOSE

| (a) Connect the outlet heater water hose with the marking (green) facing up and engage the clip within the area shown in the illustration. NOTICE: Do not apply excessive force to the outlet heater water hose. |

|

23. INSTALL AIR CONDITIONING TUBE AND ACCESSORY ASSEMBLY

(a) Remove the vinyl tape from the air conditioning tube and accessory assembly.

(b) Apply sufficient compressor oil to 2 new O-rings and fitting surface of the air conditioning tube and accessory assembly.

Compressor Oil:

ND-OIL 8 or equivalent

(c) Install the 2 O-rings to the air conditioning tube and accessory assembly.

NOTICE:

Keep the O-ring and O-ring fitting surface free of foreign matter.

(d) Connect the air conditioning tube and accessory assembly.

| (e) Rotate the hook connector as shown in the illustration. |

|

(f) Insert the hose joint into the fitting hole securely and install the bolt.

Torque:

9.5 N·m {97 kgf·cm, 84 in·lbf}

24. INSTALL DASH PANEL HEAT INSULATOR

Click here

25. INSTALL OUTER COWL TOP PANEL SUB-ASSEMBLY

(a) Install the outer cowl top panel sub-assembly with the 11 bolts.

Torque:

12 N·m {122 kgf·cm, 9 ft·lbf}

| (b) Engage the clamp. |

|

26. INSTALL NO. 1 FRONT VENTILATOR SEAL

| (a) Engage the claws to install the No. 1 front ventilator seal. |

|

27. INSTALL WATER GUARD PLATE RH

| (a) Engage the claws to install the water guard plate RH. |

|

28. INSTALL WINDSHIELD WIPER MOTOR AND LINK

Click here

29. ADD ENGINE COOLANT

Click here

30. CHARGE AIR CONDITIONING SYSTEM WITH REFRIGERANT

Click here

31. INSPECT FOR COOLANT LEAK

Click here

32. WARM UP ENGINE

Click here

33. INSPECT FOR REFRIGERANT LEAK

Click here

34. INSTALL NO. 1 ENGINE UNDER COVER ASSEMBLY

Click here

35. INITIALIZATION SERVO MOTOR

Click here

36. PERFORM REGISTRATION

Click here

Reassembly

Reassembly

REASSEMBLY PROCEDURE 1. INSTALL AIR DUCT ASSEMBLY (a) Install the air duct assembly with the 2 nuts.

(b) Install the front panel silencer as shown in the illustration...

Ambient Temperature Sensor

Ambient Temperature Sensor

ComponentsCOMPONENTS ILLUSTRATION

*1 THERMISTOR ASSEMBLY - - RemovalREMOVAL PROCEDURE 1. REMOVE FRONT BUMPER ASSEMBLY Click here

2. REMOVE THERMISTOR ASSEMBLY (a) Disengage the clamp...

Other information:

Toyota Yaris XP210 (2020-2025) Reapir and Service Manual: Yaw Rate Sensor Signal Stuck In Range (C00632A,C05201C,C05202A,C052096)

DESCRIPTION The airbag sensor assembly has a built-in yaw rate and acceleration sensor and detects the vehicle condition. These DTCs are stored when the skid control ECU (brake actuator assembly) receives an internal malfunction signal from the yaw rate and acceleration sensor (airbag sensor assembly)...

Toyota Yaris XP210 (2020-2025) Reapir and Service Manual: Reassembly

REASSEMBLY PROCEDURE 1. INSTALL CONTROL SHAFT COVER OIL SEAL (a) Using SST and a hammer, install a control shaft cover oil seal to the control shaft cover. SST: 09307-12010 Drive in Depth: 0 to 0.5 mm (0 to 0.0197 in.) (b) Coat a new control shaft cover oil seal lip with MP grease...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Fuse Panel Description

- Engine Start Function When Key Battery is Dead

- Key Battery Replacement

- New on site

- Most important about car

Keys

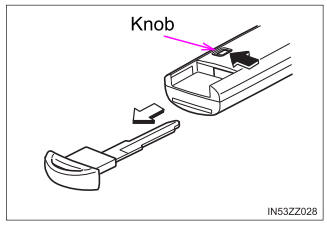

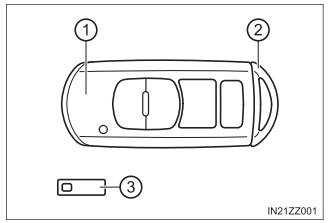

To use the auxiliary key, press the knob and pull out the auxiliary key from the smart key.