Toyota Yaris: Fuel Pump (for High Pressure) / Installation

INSTALLATION

CAUTION / NOTICE / HINT

NOTICE:

This procedure includes the installation of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

Click here

PROCEDURE

1. TEMPORARILY INSTALL FUEL PUMP ASSEMBLY

NOTICE:

When replacing the fuel pump assembly, it is necessary to replace the No. 1 fuel pipe sub-assembly with a new one.

HINT:

Perform "Inspection After Repair" after replacing the fuel pump assembly.

Click here

| (a) Turn the crankshaft pulley until the flat of the No. 2 camshaft faces the fuel pump lifter assembly. HINT: This prevents the No. 2 camshaft nose from pushing up the fuel pump lifter assembly when installing the fuel pump assembly. |

|

| (b) Apply 30 cc (1.8 cu. in.) of engine oil to the pump drive cam. |

|

(c) Apply engine oil to the fuel pump lifter assembly.

(d) Install a new fuel pump spacer gasket to the cylinder head cover sub-assembly.

| (e) Apply engine oil to the inside of the fuel pump lifter guide and the outside of the fuel pump lifter assembly. |

|

(f) Set the fuel pump lifter assembly on the fuel pump lifter guide as shown in the illustration.

HINT:

Align the stopper key of the fuel pump lifter assembly with the key groove of the fuel pump lifter guide.

| (g) Apply engine oil to a new O-ring and install it to the fuel pump assembly. NOTICE: Do not damage the O-ring. |

|

| (h) Set the fuel pump flange and fuel pump assembly on the cylinder head cover sub-assembly as shown in the illustration. |

|

(i) Temporarily install the fuel pump assembly with the 2 bolts, leaving some allowance for left and right movement.

2. INSTALL INTAKE AIR RESONATOR

(a) Install the intake air resonator to the fuel pump flange with the bolt.

3. INSTALL NO. 1 VACUUM TRANSMITTING HOSE

(a) Engage the 2 clamps and connect the No. 1 vacuum transmitting hose.

4. CONNECT ENGINE WIRE

(a) Engage the clamp and connect the engine wire.

(b) Install the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

(c) Connect the 2 connectors.

5. TEMPORARILY INSTALL NO. 1 FUEL PIPE SUB-ASSEMBLY

NOTICE:

Do not damage the seals of the union nuts of the No. 1 fuel pipe sub-assembly.

| (a) Temporarily install the bolt. |

|

(b) Temporarily install the No. 1 fuel pipe sub-assembly to the fuel delivery pipe and tighten the union nut by hand.

(c) Temporarily install the No. 1 fuel pipe sub-assembly to the fuel pump assembly and tighten the union nut by hand.

6. INSTALL FUEL PUMP ASSEMBLY

(a) Tighten the 2 bolts.

Torque:

29 N·m {296 kgf·cm, 21 ft·lbf}

(b) Connect the fuel pump assembly connector.

7. INSTALL NO. 1 FUEL PIPE SUB-ASSEMBLY

(a) Using a 17 mm union nut wrench, tighten the union nut on the fuel delivery pipe side of the No. 1 fuel pipe sub-assembly.

| *a | 17 mm Union Nut Wrench | *b | Torque Wrench Fulcrum Length |

Torque:

Specified tightening torque :

35 N·m {357 kgf·cm, 26 ft·lbf}

NOTICE:

Do not adjust the torque in the loosening direction.

HINT:

-

Calculate the torque wrench reading when changing the fulcrum length of the torque wrench.

Click here

- When using a 17 mm union nut wrench (fulcrum length of 30 mm (1.18 in.)) + torque wrench (fulcrum length of 180 mm (7.09 in.)): 30 N*m (306 kgf*cm, 22 ft.*lbf)

(b) Using a 17 mm union nut wrench, tighten the union nut on the fuel pump assembly side of the No. 1 fuel pipe sub-assembly.

Torque:

Specified tightening torque :

35 N·m {357 kgf·cm, 26 ft·lbf}

NOTICE:

Do not adjust the torque in the loosening direction.

HINT:

-

Calculate the torque wrench reading when changing the fulcrum length of the torque wrench.

Click here

- When using a 17 mm union nut wrench (fulcrum length of 30 mm (1.18 in.)) + torque wrench (fulcrum length of 180 mm (7.09 in.)): 30 N*m (306 kgf*cm, 22 ft.*lbf)

(c) Tighten the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

8. CONNECT NO. 1 WATER BY-PASS HOSE

(a) Connect the No. 1 water by-pass hose and slide the clip to secure it.

9. CONNECT NO. 8 WATER BY-PASS HOSE

(a) Connect the No. 8 water by-pass hose and slide the clip to secure it.

10. INSTALL NO. 2 FUEL TUBE SUB-ASSEMBLY

(a) Connect the No. 2 fuel tube sub-assembly to the fuel pump assembly and fuel delivery pipe.

(b) Install the No. 2 fuel tube sub-assembly with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

11. INSTALL FUEL HOSE CLAMP

(a) Install the fuel pipe clamp to the No. 2 fuel tube sub-assembly.

12. CONNECT NO. 1 FUEL TUBE SUB-ASSEMBLY

(a) Connect the No. 1 fuel tube sub-assembly to the No. 2 fuel tube sub-assembly.

Click here

13. INSTALL NO. 1 VACUUM SWITCHING VALVE ASSEMBLY

Click here

14. INSTALL NO. 1 ENGINE COVER SUB-ASSEMBLY

Click here

15. INSTALL OUTER COWL TOP PANEL SUB-ASSEMBLY

Click here

16. INSTALL WATER GUARD PLATE RH

Click here

17. INSTALL FRONT NO. 1 VENTILATOR SEAL

Click here

18. INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

Click here

19. CONNECT CABLE TO NEGATIVE AUXILIARY BATTERY TERMINAL

Click here

20. INITIALIZATION AFTER RECONNECTING AUXILIARY BATTERY TERMINAL

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

Click here

21. INSPECT FOR FUEL LEAK

Click here

22. PERFORM INITIALIZATION

(a) Perform "Inspection After Repair" after replacing the fuel pump assembly.

Click here

Inspection

Inspection

INSPECTION PROCEDURE 1. INSPECT FUEL PUMP ASSEMBLY (a) Measure the resistance according to the value(s) in the table below. Standard Resistance: Tester Connection Condition Specified Condition D24-1 - D24-2 20°C (68°F) 0...

Fuel Pump Ecu

Fuel Pump Ecu

ComponentsCOMPONENTS ILLUSTRATION

*1 FUEL PUMP CONTROL ECU BRACKET *2 FUEL PUMP CONTROL ECU *3 DECK TRIM SIDE PANEL ASSEMBLY RH - -

N*m (kgf*cm, ft...

Other information:

Toyota Yaris XP210 (2020-2025) Reapir and Service Manual: ABS Operates Before Necessary When Braking

DESCRIPTION Troubleshooting for when ABS operates too soon due to a noisy signal from the speed sensor, a difference in output, etc. CAUTION / NOTICE / HINT NOTICE: After replacing or removing and installing a speed sensor, perform Dealer Mode (Signal Check) inspection to confirm that the speed sensors are operating correctly...

Toyota Yaris XP210 (2020-2025) Reapir and Service Manual: Installation

INSTALLATION PROCEDURE 1. INSTALL REAR DIFFERENTIAL SUPPORT (a) Install the differential support to the rear differential carrier assembly with 3 new bolts. Torque: 120 N·m {1224 kgf·cm, 89 ft·lbf} 2. INSTALL REAR DIFFERENTIAL DYNAMIC DAMPER (a) Install the rear differential dynamic damper to the differential support with 2 bolts...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Speedometer, Odometer, Trip Meter and Trip Meter Selector

- How to use USB mode

- Brake System Control Module "A" System Voltage System Voltage Low (C137BA2)

- New on site

- Most important about car

Keys

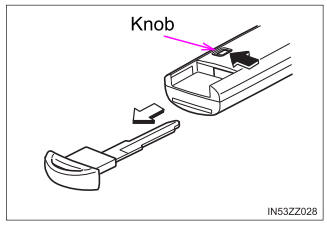

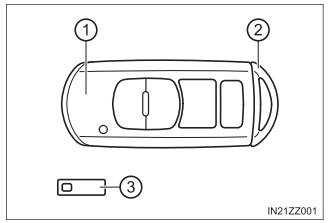

To use the auxiliary key, press the knob and pull out the auxiliary key from the smart key.