Toyota Yaris: Sfi System / Initialization

INITIALIZATION

Inspection After Repair

Perform Learning Value Reset and Idle Learning after replacing or servicing parts related to engine operation. Details on procedures required are indicated by an asterisk and a number, and are explained in detail following the table.

| mostbet casino Part Replaced | Engine Operation | Learning Value Reset*1 | Idle Learning*2 |

|---|---|---|---|

| - | ○ | ○ |

| Engine assembly | - | ○ | ○ |

| Confirm the following and perform Learning Value Reset and Idle Learning when one or more of the following conditions is met:

| ○ | ○ |

| None of the conditions in the list above are met. | - | - | |

| Turbocharger sub-assembly | - | ○ | - |

| Knock control sensor*4 | - | - | - |

- ○: Necessary.

- -: Unnecessary.

NOTICE:

Engine learned values cannot be reset by disconnecting the cable from the negative (-) auxiliary battery terminal or removing the EFI-MAIN NO. 1 fuse.

-

*1: Learning Value Reset

- Connect the GTS to the DLC3.

- Turn the ignition switch to ON.

- Turn the GTS on.

- Enter the following menus: Powertrain / Engine / Utility / Learning Value Reset.

-

Confirm the following conditions as instructed on the screen.

- - Ignition switch to ON

- - Engine stopped

- - Auxiliary battery voltage is higher than 9 V

-

After confirming, select "Next" and initialize the learned value.

HINT:

If a message indicating learned value initialization failure is displayed on the screen, confirm the execution conditions, and perform learned value initialization again.

-

After the completion of learned value initialization, confirm the air fuel ratio learned values(A/F Learn Value Idle Bank 1, A/F Learn Value Low Bank 1, A/F Learn Value Mid No.1 Bank 1, A/F Learn Value Mid No.2 Bank 1, A/F Learn Value High Bank 1, A/F Learn Value Idle (Port) Bank 1, A/F Learn Value Low (Port) Bank 1, A/F Learn Value Mid No.1 (Port) Bank 1, A/F Learn Value Mid No.2 (Port) Bank 1, A/F Learn Value High (Port) Bank 1, in the Data List.

If 0 is displayed for all of the air fuel ratio learned values, initialization has completed correctly.

If a value other than 0 is displayed for one of the air fuel ratio learned values, perform initialization again. After initialization, confirm the air fuel ratio learned values. If a value other than 0 is displayed, replace the ECM.

-

*2: Idle Learning

- Turn the ignition switch off and wait for at least 30 seconds.

-

Start the engine and warm it up with the air conditioning and all accessories off, until the engine coolant temperature is 80°C (176°F) or higher.

HINT:

Learning starts when the engine coolant temperature is 80°C (176°F) or higher.

- After the engine is warmed up, allow it to idle for 5 minutes with the air conditioning and all accessories off.

-

Confirm that the idle speed is within the standard range.

Standard:

Engine Idle Speed

950 to 1050 rpm

HINT:

- Be sure to perform this step with the A/C switch and all accessories off.

- Make sure that neutral is selected.

-

*3: Perform Learning Value Reset and Idle Learning after replacing the throttle body with motor assembly or cleaning deposits from the throttle body with motor assembly.

After that, check the idle speed. If the idle speed is out of the specified range, perform the following procedure.

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

HINT:

History information for driving and stopping is necessary to update Idle Learning.

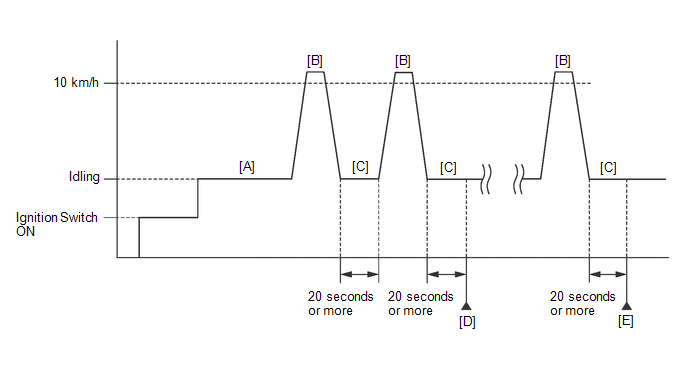

- Warm up the engine (engine coolant temperature of 80°C (176°F) or higher) with the A/C switch and all accessories off [A].

- Drive the vehicle at a speed of 10 km/h (6 mph) or more [B].

- Idle the engine for 20 seconds or more [C].

-

Repeat procedure [B] and [C], and check that the idle speed is within the specified range [D].

Standard:

Engine Idle Speed

950 to 1050 rpm

HINT:

- Be sure to perform this step with the A/C switch and all accessories off.

- Make sure that neutral is selected.

- If the idle speed is still out of the specified range, repeat procedure [B] and [C] until the idle speed is within the specified range [E].

- *4: Drive the vehicle for a short while after replacing the knock control sensor, and check if knocking occurs. If knocking occurs, drive the vehicle until knocking stops.

CLEAR HEAVY KNOCK HISTORY

HINT:

This function initializes the stored history data when the piston rings are replaced.

(a) Connect the GTS to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the GTS on.

(d) Enter the following menus: Powertrain / Engine / Utility / Heavy Knock History / Clear History.

Powertrain > Engine > Utility| Tester Display |

|---|

| Heavy Knock History |

(e) Initialize the history data according to the GTS screen instructions.

Registration

Registration

REGISTRATION CAUTION / NOTICE / HINT PROCEDURE 1. VIN or FRAME NUMBER NOTICE: The Vehicle Identification Number (VIN) or frame number must be written into a replacement ECM...

Problem Symptoms Table

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE HINT:

Use the table below to help determine the cause of problem symptoms. If multiple suspected areas are listed, the potential causes of the symptoms are listed in order of probability in the "Suspected Area" column of the table...

Other information:

Toyota Yaris XP210 (2020-2025) Reapir and Service Manual: System Voltage Circuit Short to Ground or Open (P056014)

MONITOR DESCRIPTION The auxiliary battery supplies electricity to the ECM even when the ignition switch is off. This power allows the ECM to store data such as DTC history, Freeze Frame Data and fuel trim values. If the auxiliary battery voltage falls below a minimum level, the memory is cleared and the ECM determines that there is a malfunction in the power supply circuit...

Toyota Yaris XP210 (2020-2025) Reapir and Service Manual: How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT HINT: *: Use the GTS. PROCEDURE 1. VEHICLE BROUGHT TO WORKSHOP NEXT 2. CUSTOMER PROBLEM ANALYSIS HINT: In troubleshooting, confirm that the problem symptoms have been accurately identified...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Adjustment

- Headlights

- Removal

- New on site

- Most important about car

Liftgate/Trunk Lid

WARNING

Never allow a person to ride in the luggage compartment/trunk

Allowing a person to ride in the luggage compartment/trunk is dangerous. The person in the luggage compartment/trunk could be seriously injured or killed during sudden braking or a collision.

Do not drive with the liftgate/trunk lid open