Toyota Yaris: Clutch Unit / Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during the cover and disc clutch set removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed | Link |

|---|---|---|---|

| Front wheel alignment adjustment | ECU Data Initialization | Active torque split AWD system |

|

| Calibration |

|

|

NOTICE:

When the manual transaxle assembly is removed, be sure to use a new clutch release cylinder with bearing assembly and new installation bolts. Removal of the manual transaxle assembly allows the compressed clutch release cylinder with bearing assembly to return to its original position. Dust from the moving section may damage the seal of the clutch release cylinder with bearing assembly, possibly causing clutch fluid leaks.

HINT:

When the cable is disconnected / reconnected to the auxiliary battery terminal, systems temporarily stop operating. However, each system has a function that completes learning the first time the system is used.

-

Learning completes when vehicle is driven

Effect/Inoperative Function When Necessary Procedures are not Performed

Necessary Procedures

Link

Lane tracing assist system

Drive the vehicle straight ahead at 35 km/h (22 mph) or more for 5 second or more.

Pre-collision system

Stop and start system

Drive the vehicle until stop and start control is permitted (approximately 5 to 60 minutes)

-

Learning completes when vehicle is operated normally

Effect/Inoperative Function When Necessary Procedures are not Performed

Necessary Procedures

Link

Power door lock control system

- Back door opener

Perform door unlock operation with door control switch or electrical key transmitter sub-assembly switch.

Air conditioning system

After the ignition switch is turned to ON, the servo motor standard position is recognized.

-

PROCEDURE

1. REMOVE MANUAL TRANSAXLE ASSEMBLY

Click here

2. REMOVE BLEEDER CLUTCH RELEASE TUBE

| (a) Using a 10 mm union nut wrench, disconnect the bleeder clutch release tube from the clutch release bleeder sub-assembly. |

|

(b) Remove the bolt and bleeder clutch release tube from the manual transaxle assembly.

| (c) Remove the clamp from the bleeder clutch release tube. |

|

3. REMOVE CLUTCH RELEASE BLEEDER SUB-ASSEMBLY

| (a) Using a 10 mm union nut wrench, disconnect the clutch release cylinder to bleeder tube from the clutch release bleeder sub-assembly. |

|

| (b) Remove the bolt and clutch release bleeder sub-assembly from the manual transaxle assembly. |

|

4. REMOVE CLUTCH RELEASE BEARING PLATE

| (a) Remove the clutch release bearing plate from the clutch release cylinder with bearing assembly. NOTICE: When removing the manual transaxle assembly, the clutch release bearing plate could fall out. |

|

5. REMOVE CLUTCH RELEASE CYLINDER WITH BEARING ASSEMBLY

| (a) Remove the clutch tube boot from the manual transaxle assembly. |

|

| (b) Remove the 3 bolts and clutch release cylinder with bearing assembly together with clutch release cylinder to bleeder tube from the manual transaxle assembly. |

|

6. REMOVE CLUTCH RELEASE CYLINDER TO BLEEDER TUBE

(a) Mount the clutch release cylinder with bearing assembly in a soft jaw vise.

| (b) Using a 10 mm union nut wrench, remove the clutch release cylinder to bleeder tube from the clutch release cylinder with bearing assembly. |

|

7. REMOVE COVER AND DISC CLUTCH SET

| (a) Put matchmarks on the clutch cover assembly and the flywheel sub-assembly. |

|

(b) Loosen each bolt 180° at a time until the spring tension is released.

(c) Remove the 6 bolts and pull off the cover and disc clutch set.

NOTICE:

- Do not drop the clutch disc assembly.

- Keep the lined part of the clutch disc assembly, the pressure plate, and the surface of the flywheel sub-assembly away from oil and foreign matter.

Components

Components

COMPONENTS ILLUSTRATION

*1 COVER AND DISC CLUTCH SET *2 MANUAL TRANSAXLE ASSEMBLY *3 CLUTCH RELEASE CYLINDER WITH BEARING ASSEMBLY *4 CLUTCH TUBE BOOT *5 CLUTCH RELEASE CYLINDER TO BLEEDER TUBE *6 CLUTCH RELEASE BLEEDER SUB-ASSEMBLY *7 BLEEDER CLUTCH RELEASE TUBE *8 CLAMP *9 CLUTCH RELEASE BEARING PLATE - -

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft...

Inspection

Inspection

INSPECTION PROCEDURE 1. INSPECT CLUTCH DISC ASSEMBLY (a) Using a vernier caliper, measure the rivet head depth. Minimum Rivet Head Depth: 0.3 mm (0...

Other information:

Toyota Yaris XP210 (2020-2024) Reapir and Service Manual: Engine Coolant Temperature Receiver Gauge Malfunction

DESCRIPTION In this circuit, the combination meter assembly receives engine coolant temperature signals from the ECM via CAN communication. The combination meter assembly displays an engine coolant temperature warning based on the data received from the ECM...

Toyota Yaris XP210 (2020-2024) Reapir and Service Manual: Left Rear Wheel Speed Sensor Circuit Short to Battery (C050C12)

DESCRIPTION Refer to DTC C050C1F. Click here DTC No. Detection Item DTC Detection Condition Trouble Area DTC Output from C050C12 Left Rear Wheel Speed Sensor Circuit Short to Battery The speed sensor short signal is ON continuously for 0...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- How to connect USB port/Auxiliary jack

- Diagnostic Trouble Code Chart

- Battery Monitor Module General Electrical Failure (P058A01)

- New on site

- Most important about car

Refueling

Before refueling, close all the doors, windows, and the liftgate/trunk lid, and switch the ignition OFF.

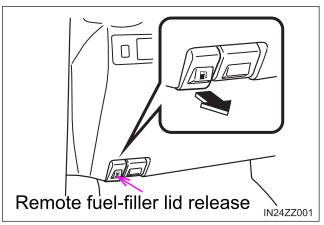

To open the fuel-filler lid, pull the remote fuel-filler lid release.